About us

The aluminum and Zinc Foundry LLC – Resen produces high quality aluminum and zinc effluences by using a technology of high pressure casting.

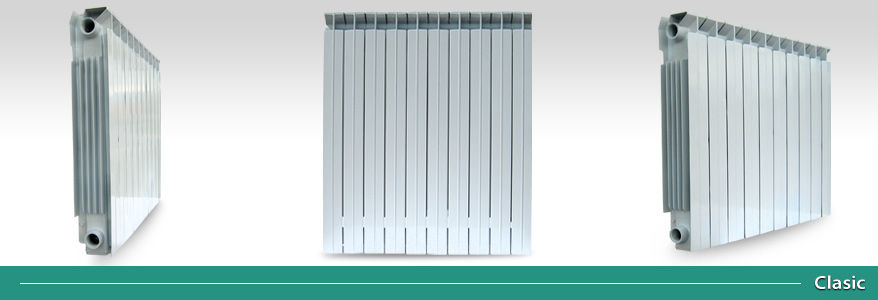

Our company follows the production program of the factory producing heating items – Algreta, and also introduced new types of radiators that suit the worldwide quality standards and which can be used in the world’s largest heating systems, as is the example in Moscow and throughout Russia and Macedonia.

The factory is equipped with Italian machinery used for pressure foundry, heating chamber machines ranging from 20 to 180 t used for zink casting effluences and cold chamber machines ranging from 180 to 1100 t also used for casting aluminum effluences. The metal melting is central but mostly we work according to the wishes of our clients, with more types of aluminum alloys.

There is a special part in our Foundry equipped with a machinery park used for producing and processing of radiator parts where we cut, weld, examine and assemble all of the radiator parts.

The manufacturing process goes on without releasing the waste waters and other materials into the environment. The water is remanufactured inside our factory compound where it’s used again as a clean technological water.

In the factory there is a paint shop section where the radiators are being painted with an electrostatic white paint RAL 9016.